In the world of rice processing, precision and quality are paramount. Whether you're operating a small-scale milling unit or a large industrial plant, the tools you use can dramatically affect the quality of your final product. One such tool that has revolutionized the rice milling process is the rice abrasive stone—a critical component in achieving a polished, high-quality finish in milled rice.

Rice abrasive stones are specially designed grinding tools used in rice polishing machines. These stones help remove the bran layer from the surface of brown rice, transforming it into the shiny white rice we often see on our plates. Unlike traditional polishing techniques that may leave rice grains broken or unevenly polished, rice abrasive stones offer a uniform and efficient polishing process.

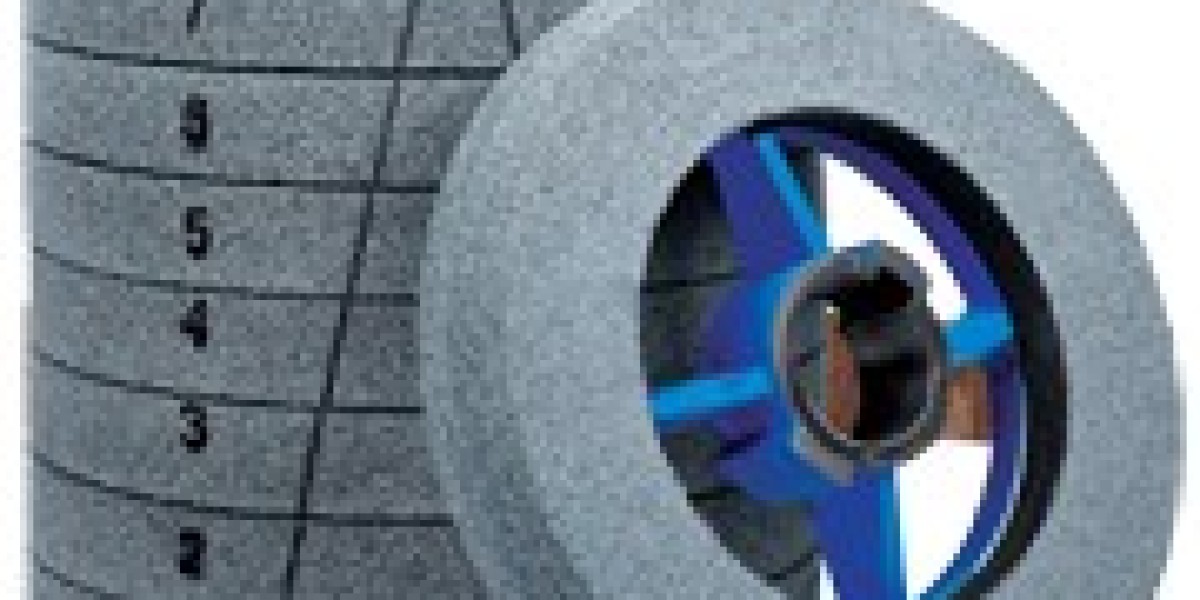

Made from highly durable materials like silicon carbide or alumina, these stones are engineered for optimal wear resistance and long-lasting performance. They come in various sizes and grit levels, allowing millers to choose the right stone for different types of rice and desired levels of polish.

Midway through any rice milling operation, the rice abrasive stone takes center stage. It's during this phase that the most critical transformation occurs—from a rough, unrefined grain to a smooth, polished product ready for market. The abrasive action gently strips away the outer bran layer without damaging the core grain, preserving both the nutritional value and the integrity of the rice.

What's more, the use of high-quality rice abrasive stones can significantly improve milling efficiency. Their superior design minimizes breakage, reduces processing time, and results in higher yields of polished rice. This not only ensures consistent product quality but also cuts down operational costs over time.

Sustainability is another added advantage. Many modern rice abrasive stones are designed to be environmentally friendly, producing less dust and requiring fewer replacements. This makes them a preferred choice for forward-thinking rice millers who are looking to reduce their environmental footprint.

In conclusion, the rice abrasive stone is more than just a component in a machine—it’s a cornerstone of quality rice production. If you're in the rice milling business, investing in the right abrasive stone is a decision that will pay dividends in both product quality and operational efficiency.