In the fast-evolving world of industrial automation, flexibility, interoperability, and ease of programming have become key requirements for Programmable Logic Controllers (PLCs). CODESYS PLC (Controller Development System) has emerged as a leading software platform that enables engineers and developers to program and deploy powerful automation solutions. Known for its open-source adaptability, user-friendly interface, and broad device compatibility, CODESYS PLC is transforming how industries implement control systems.

What is CODESYS PLC?

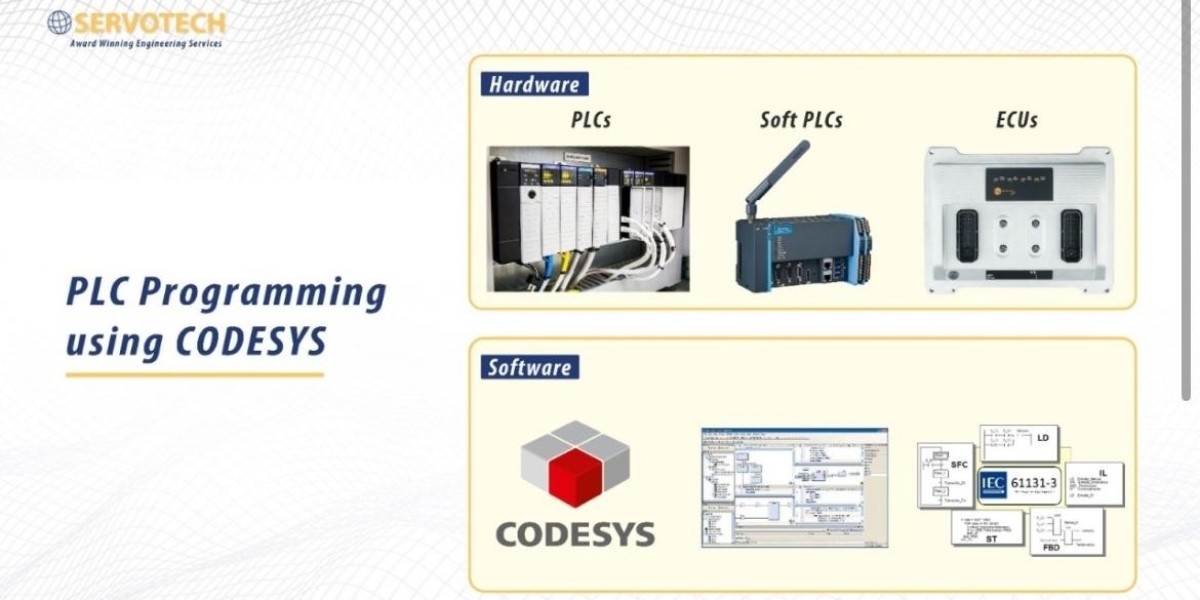

CODESYS PLC is a hardware-independent IEC 61131-3 programming environment for industrial automation applications. Developed by 3S-Smart Software Solutions, CODESYS allows engineers to develop controller applications using standardized programming languages like Structured Text (ST), Ladder Diagram (LD), Function Block Diagram (FBD), Instruction List (IL), and Sequential Function Chart (SFC).

Unlike traditional PLC systems locked into specific hardware brands, CODESYS is hardware-agnostic, meaning it can run on a wide variety of devices—whether it's a dedicated PLC, an industrial PC, or even a Raspberry Pi. This flexibility significantly reduces development costs and enhances scalability across diverse industrial applications.

Key Features of CODESYS PLC

1. IEC 61131-3 Compliance

CODESYS supports all five standard programming languages defined by IEC 61131-3, offering flexibility and choice based on the developer's preference or the specific application requirements.

2. Integrated Development Environment (IDE)

The CODESYS IDE is intuitive and feature-rich, offering tools for debugging, simulation, and version control. Its graphical and textual editors streamline application development.

3. Real-Time Control

CODESYS can turn standard hardware into powerful real-time controllers. Real-time tasks ensure high-performance and deterministic control necessary for complex automation processes.

4. Extensive Hardware Support

CODESYS works with a broad range of devices from manufacturers like WAGO, Beckhoff, Schneider Electric, and Bosch Rexroth. This interoperability simplifies integration in mixed-vendor environments.

5. Fieldbus Integration

CODESYS supports standard fieldbus protocols like EtherCAT, CANopen, Modbus, and PROFINET, enabling seamless communication with sensors, actuators, and other networked devices.

6. Web and Remote Visualization

With CODESYS WebVisu and CODESYS HMI, users can create web-based dashboards and remote HMIs for real-time monitoring and control, accessible from any browser-enabled device.

7. Motion Control and CNC

CODESYS includes modules for motion control, robotics, and CNC, making it suitable for highly dynamic and precise applications in manufacturing and packaging industries.

Benefits of Using CODESYS PLC

1. Vendor Independence

One of CODESYS’s standout features is its independence from specific hardware vendors. Users can select the most appropriate or cost-effective hardware without being tied to proprietary ecosystems.

2. Cost Efficiency

By using general-purpose hardware with CODESYS, organizations can avoid expensive proprietary controllers while achieving similar, if not better, performance.

3. Scalability

CODESYS applications can scale from small embedded controllers to large distributed systems, making it ideal for projects of all sizes—from simple automation tasks to complex industrial systems.

4. Rapid Development

The development environment supports simulation and debugging without requiring physical hardware. This allows developers to test applications thoroughly before deployment, reducing on-site troubleshooting time.

5. Community and Ecosystem

CODESYS has a strong global developer community and a marketplace for add-ons and libraries, helping users access additional features and prebuilt solutions that accelerate development.

Applications of CODESYS PLC

CODESYS is used across multiple industries due to its flexibility and robust capabilities:

Factory Automation: Control of conveyors, robotic arms, production lines, and safety systems.

Building Automation: Lighting, HVAC, and security systems using intelligent, responsive controls.

Renewable Energy: Monitoring and managing wind turbines, solar farms, and battery storage systems.

Automotive Manufacturing: Precision motion and robotic control in assembly lines.

Food and Beverage: Ensuring consistent product quality and compliance in automated processes.

CODESYS PLC in Industry 4.0

The rise of Industry 4.0 and smart manufacturing has increased the demand for flexible, connected, and data-driven control systems. CODESYS aligns perfectly with these trends by supporting modern protocols like OPC UA, MQTT, and REST APIs for data exchange with cloud platforms, MES, and ERP systems.

With edge computing gaining ground, many organizations deploy CODESYS on industrial PCs or edge devices to perform local processing and analytics before sending data to the cloud. This reduces latency and improves system responsiveness.

Challenges and Considerations

While CODESYS offers many benefits, it’s essential to be aware of potential challenges:

Initial Learning Curve: For teams unfamiliar with IEC 61131-3 or transitioning from proprietary PLC platforms, some training may be needed.

License Management: Although the IDE is free, deploying applications on certain devices may require a runtime license.

Security: As with any connected control system, cybersecurity measures must be in place to prevent unauthorized access.

The Future of CODESYS PLC

CODESYS continues to evolve, with ongoing updates focused on cloud integration, cybersecurity, and support for AI and machine learning. As automation systems become more complex and interconnected, CODESYS is positioning itself as a forward-looking solution that meets the demands of modern industrial environments.

Efforts to integrate CODESYS with containerization platforms like Docker also suggest a future where automation control can be more modular, portable, and easier to deploy.

Conclusion

CODESYS PLC by Servotechinc stands as a versatile and powerful platform for modern industrial control applications. Its openness, scalability, and broad feature set make it a compelling alternative to proprietary PLC systems. By enabling cost-effective development, cross-platform compatibility, and enhanced functionality, CODESYS empowers engineers and businesses to build smarter, more adaptive automation solutions that align with the future of industry.

Whether you are upgrading legacy systems, launching new automation projects, or transitioning to Industry 4.0, CODESYS offers the tools and flexibility to bring your vision to life.