In today’s competitive engineering landscape, the demand for high-performance, reliable, and cost-effective products is at an all-time high. To meet these challenges, companies must make smarter design decisions earlier in the development cycle. That’s where Finite Element Analysis (FEA) comes into play. As a vital component of modern engineering, FEA enables detailed simulation and analysis of physical systems—long before a prototype is built.

At Servotech Inc., our specialized FEA Engineering Services help you optimize product designs, reduce development costs, and accelerate time-to-market. Whether you're assessing structural integrity, thermal behavior, or dynamic performance, our expert team provides the insights you need to move forward with confidence.

What is Finite Element Analysis?

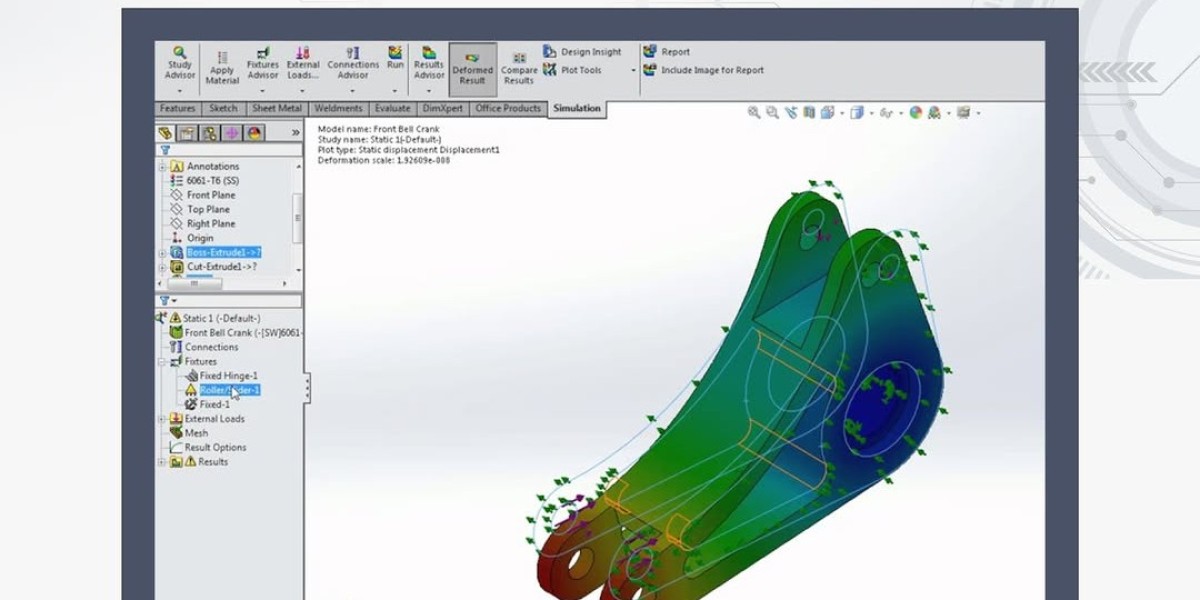

Finite Element Analysis (FEA) is a computational method used to predict how a product or component will react to real-world forces, such as heat, vibration, fluid flow, impact, and mechanical stress. It divides a complex structure into smaller, manageable elements, applying mathematical equations to simulate behavior under various conditions.

FEA allows engineers to visualize stress distribution, identify weak points, and refine designs for strength, efficiency, and reliability—all in a virtual environment. This reduces the need for costly physical prototypes and helps prevent design flaws before they reach production.

Servotech’s FEA Engineering Capabilities

At Servotech, we bring deep technical expertise and industry experience to every FEA project. Our services span a wide range of analysis types and industries, enabling our clients to develop better products with fewer iterations.

✅ Structural Analysis

Our team conducts linear and nonlinear static structural analysis to evaluate stress, strain, and displacement in complex geometries. We help identify stress concentrations, assess load-bearing capacity, and ensure compliance with design standards.

✅ Thermal Analysis

We simulate heat transfer, thermal distribution, and temperature-induced deformation in products exposed to varying environmental or operational conditions. Our thermal analysis helps prevent overheating, warping, and failure in temperature-sensitive components.

✅ Dynamic & Modal Analysis

Dynamic analysis evaluates how structures respond to time-varying loads, impacts, or vibrations. Modal analysis helps determine natural frequencies and mode shapes, ensuring systems operate safely away from resonance conditions.

✅ Fatigue & Life Cycle Analysis

Our fatigue assessments predict product life based on cyclic loading conditions. We help identify potential failure points and optimize designs for durability and longevity under repeated use.

✅ Buckling & Stability Analysis

For slender or load-bearing structures, we conduct buckling analysis to assess stability under compressive forces. This is critical for preventing collapse or deformation in critical components.

✅ Thermo-Mechanical Coupled Analysis

In cases where both thermal and mechanical loads impact performance, we perform coupled analysis to ensure your design performs reliably under real-world multi-physics conditions.

✅ Optimization & Design Iteration

FEA isn’t just about validation—it’s a powerful tool for design optimization. We use simulation results to refine material selection, geometry, and configuration for better performance and lower cost.

Tools & Technologies We Use

Servotech employs industry-leading FEA software tools, including:

ANSYS

SolidWorks Simulation

Autodesk Inventor Nastran

ABAQUS

COMSOL Multiphysics

Our advanced toolset allows for high-fidelity simulations and tailored solutions, whether you’re working on components, assemblies, or full systems.

Industries We Serve

Our FEA services support a wide range of sectors, each with unique challenges and performance requirements:

Automotive – Structural analysis of chassis, crash simulations, engine thermal analysis, fatigue life prediction.

Aerospace & Defense – Lightweight design validation, high-load simulations, vibrational response under flight conditions.

Industrial Equipment – Load assessments for machinery, structural integrity of frames and enclosures.

Medical Devices – Biomechanical modeling, stress testing for implantable devices, heat analysis in electronic components.

Consumer Products – Material behavior under daily use, impact resistance testing, product durability analysis.

Energy & Utilities – Pressure vessel simulation, turbine blade analysis, temperature effects on energy systems.

Why Choose Servotech for FEA Engineering?

At Servotech, we combine technical rigor with a client-first approach. Here’s why companies choose us as their trusted FEA partner:

✅ Experienced Engineers

Our team includes mechanical, thermal, and structural engineers with years of real-world experience. We understand the nuances of both analysis and design, ensuring actionable, practical solutions.

✅ Custom Solutions

Every project is unique. We tailor our simulations to your specific materials, loading conditions, and performance goals.

✅ Design Integration

We don’t stop at analysis—we integrate FEA directly into your design process. This iterative approach minimizes redesign cycles and enhances product development efficiency.

✅ Speed & Accuracy

With high-performance computing resources and streamlined workflows, we deliver fast turnaround times without compromising accuracy.

✅ Compliance & Standards

We ensure your designs meet relevant regulatory and industry standards, including ASME, ISO, and MIL-SPEC, depending on application.

The Servotech Process

We follow a proven methodology to ensure accurate, reliable, and insightful analysis:

Project Consultation – We begin with a deep dive into your product requirements, application context, and objectives.

CAD & Preprocessing – Geometry is cleaned, meshed, and prepared for analysis using best practices for element size and quality.

Simulation Setup – Material properties, boundary conditions, loads, and constraints are defined based on real-world conditions.

Analysis & Validation – Simulations are run and results validated through cross-checks, theoretical benchmarks, or test data.

Design Recommendations – We provide detailed reports, visualizations, and design optimization strategies.

Ongoing Support – From design revisions to production support, we remain available as your engineering partner throughout the lifecycle.

Conclusion

FEA Engineering Services by servotechinc are a critical asset in modern product development. By leveraging simulation early in the design process, companies can reduce prototyping costs, accelerate development cycles, and produce more reliable, high-performance products.