In today's rapidly evolving engineering landscape, Computer-Aided Design (CAD) and Finite Element Analysis (FEA) have become indispensable tools for product development and optimization. These technologies enable engineers to create detailed digital models and simulate real-world conditions, leading to more efficient and reliable designs.

Understanding CAD and FEA

Computer-Aided Design (CAD):

CAD involves the use of software applications to create precise 2D or 3D models of physical components. Tools like AutoCAD, Inventor, SolidWorks, and Creo facilitate the development of detailed geometric representations, allowing for comprehensive visualization and modification of designs before physical prototypes are made.

Finite Element Analysis (FEA):

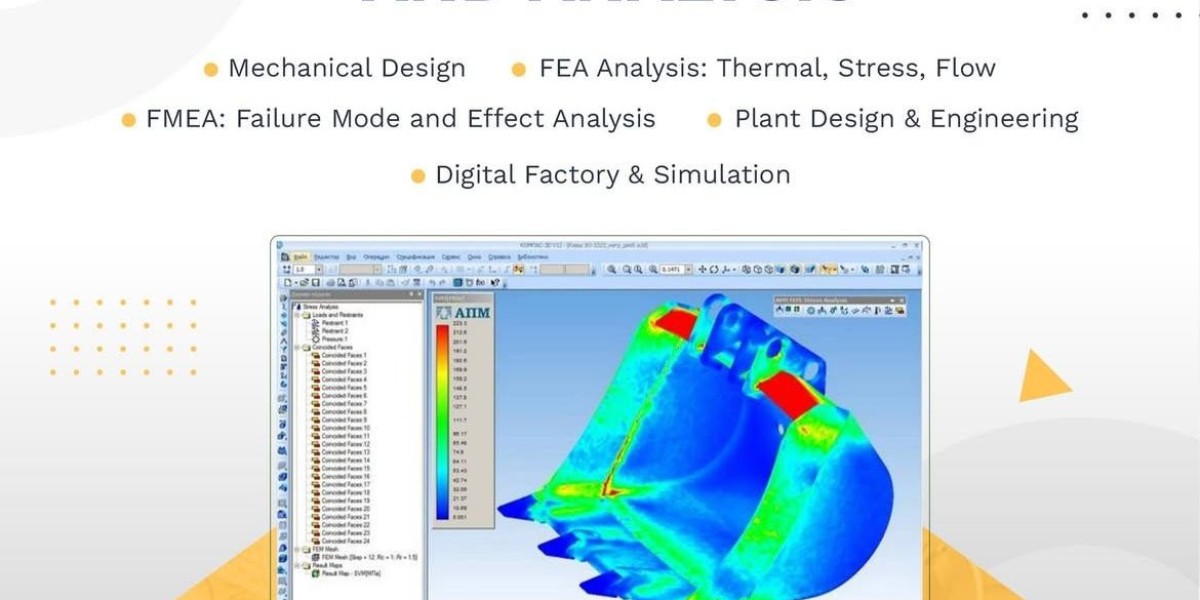

FEA is a computational technique used to predict how products react to real-world forces, such as heat, vibration, and other physical effects. By breaking down complex structures into smaller elements, FEA software can simulate and analyze the behavior of each component under various conditions, providing insights into potential performance issues.

The Synergy of CAD and FEA in Engineering

Integrating CAD and FEA engineering services allows engineers to design and analyze products within a unified digital environment. This integration streamlines the development process, enabling rapid iterations and refinements based on simulation results. For instance, a design created in CAD can be directly imported into FEA software for stress analysis, facilitating immediate feedback and optimization.

Applications Across Industries

The combined use of CAD and FEA spans various industries, including:

Aerospace: Designing and analyzing flight control systems and structural components to ensure safety and performance.

Automotive: Optimizing vehicle structures for weight reduction while maintaining structural integrity.

Manufacturing: Developing machinery and equipment with enhanced durability and efficiency.

Benefits of CAD/FEA Engineering Services

Engaging specialized CAD/FEA engineering services offers several advantages:

Cost Reduction: By identifying potential design flaws early through simulation, companies can avoid costly physical prototypes and rework.

Improved Performance: Simulations enable the optimization of designs for better performance under specific conditions.

Accelerated Time-to-Market: Streamlined design and analysis processes lead to faster product development cycles.

Servotech Inc.: Expertise in CAD/FEA Design and Analysis

Servotech Inc. specializes in providing comprehensive CAD/FEA design and analysis services. Utilizing advanced software tools, their team designs mechanical systems with 3D solid modeling, ensuring adherence to geometric dimensioning and tolerancing standards. They integrate these designs with FEA software to simulate conditions such as stress, temperature, and fluid dynamics, offering clients precise and efficient engineering solutions.

Conclusion

The integration of CAD and FEA in engineering services by Servotech has revolutionized the way products are designed and analyzed. By leveraging these technologies, companies can achieve optimized designs, reduce costs, and accelerate development timelines. Servotech Inc.'s expertise in this domain exemplifies the benefits of adopting advanced simulation tools in modern engineering practices.