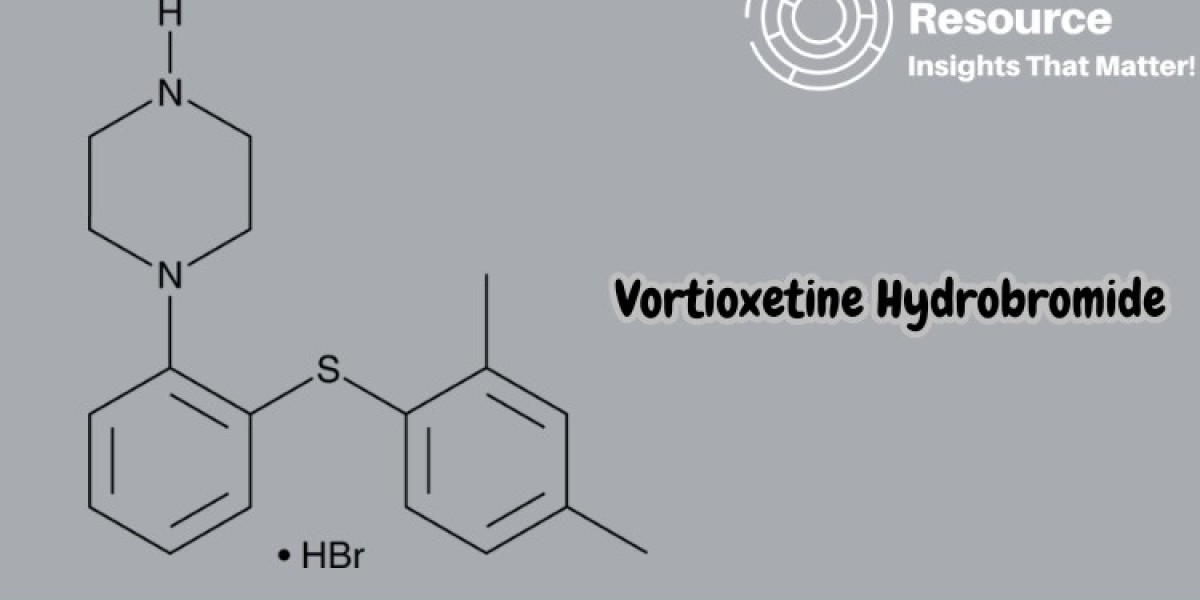

Vortioxetine Hydrobromide is an essential pharmaceutical compound used in treating major depressive disorder (MDD). As a selective serotonin reuptake inhibitor and serotonin receptor modulator, Vortioxetine has gained popularity due to its effectiveness and favorable side-effect profile. However, the high costs associated with its production necessitate a strategic approach to cost management for pharmaceutical companies. Procurement Resource provides comprehensive Vortioxetine Hydrobromide Production Cost Reports, offering businesses valuable insights to understand their cost structure and enhance cost efficiency in a competitive market.

Why Vortioxetine Hydrobromide is Important

Vortioxetine Hydrobromide, an antidepressant sold under various brand names, has become a crucial medication for managing symptoms of depression, helping to improve mood, sleep, appetite, and energy levels. Its unique mechanism of action, which includes inhibiting serotonin reuptake and modulating receptor activity, contributes to its efficacy in treating depression with minimal cognitive side effects.

Request a Free Sample for Vortioxetine Hydrobromide Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/vortioxetine-hydrobromide/request-sample

Given the increasing prevalence of mental health issues worldwide, demand for effective treatments like Vortioxetine Hydrobromide continues to rise. With production costs high due to stringent regulatory requirements and complex synthesis, understanding the cost structure is crucial for companies aiming to make this essential medication accessible and affordable.

Key Factors Driving Vortioxetine Hydrobromide Production Costs

The production cost of Vortioxetine Hydrobromide is influenced by multiple factors, including raw material expenses, energy consumption, labor, technology, and regulatory compliance. Our Vortioxetine Hydrobromide Production Cost Reports provide a detailed analysis of each factor, helping pharmaceutical companies gain comprehensive insight into their expenses and identify cost-saving opportunities.

1. Raw Material Costs

The synthesis of Vortioxetine Hydrobromide involves specific high-purity chemical compounds and reagents that are essential for producing the active pharmaceutical ingredient (API). The cost of these raw materials can vary based on quality, availability, and market demand.

High-Purity Chemicals and Reagents: As a high-quality pharmaceutical product, Vortioxetine Hydrobromide requires specialized reagents, often sourced from international suppliers. These compounds are subject to strict quality standards, driving up the production cost.

Supply Chain and Availability: Due to the specific requirements of pharmaceutical manufacturing, any disruption in the supply chain can impact the cost of raw materials. Global shortages or logistical delays can lead to price hikes, impacting overall production expenses.

Pharmaceutical companies must closely monitor raw material costs to manage production expenses effectively. Establishing reliable supplier partnerships and maintaining safety stocks are common strategies to mitigate the risk of supply disruptions and control costs.

2. Energy Costs

Producing Vortioxetine Hydrobromide is an energy-intensive process, requiring large amounts of electricity and heating to sustain chemical reactions and maintain equipment. Given the high energy requirements, any fluctuations in energy prices can significantly affect production costs.

Electricity and Heating Costs: Maintaining consistent energy input is crucial for pharmaceutical manufacturing. Rising energy costs due to fuel price fluctuations or regional energy policies can directly impact production expenses.

Energy-Efficient Technologies: Investing in energy-efficient machinery and optimizing processes can help reduce energy consumption. Many companies are exploring renewable energy options, such as solar and wind, to lower their carbon footprint and support sustainable production practices.

Effective energy management strategies, such as implementing efficient equipment and exploring renewable energy, can help pharmaceutical companies manage production costs while promoting environmentally responsible practices.

3. Labor and Operational Costs

Labor is a significant factor in the production cost of Vortioxetine Hydrobromide, particularly because highly skilled personnel are needed for the production process. Strict quality control measures and regulatory requirements necessitate qualified chemists, technicians, and quality assurance staff, all of which contribute to operational costs.

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/vortioxetine-hydrobromide

Skilled Labor: The production of pharmaceutical compounds like Vortioxetine Hydrobromide requires specialized knowledge and adherence to safety protocols, making skilled labor essential. Regional labor costs vary, affecting overall production expenses.

Quality Assurance and Compliance: Ensuring quality standards in pharmaceutical production requires continuous monitoring and testing, which adds to labor and operational costs.

Efficiently managing labor and operational costs can significantly impact profitability in Vortioxetine Hydrobromide production. Training, process optimization, and investing in quality assurance can help improve production efficiency and maintain regulatory compliance.

4. Technological Advances and Maintenance

The production of Vortioxetine Hydrobromide can benefit from technological advancements that improve process efficiency, yield, and product quality. However, adopting new technology requires capital investment, which impacts production costs in the short term.

Advanced Synthesis Technologies: Innovative techniques in chemical synthesis can increase yields and reduce waste, thereby lowering production costs in the long run. Automated systems for mixing, monitoring, and quality control can streamline the process, though they come with upfront investment costs.

Equipment Maintenance: Regular maintenance of production equipment is essential to prevent breakdowns, which can cause costly delays in pharmaceutical manufacturing. Planned maintenance schedules ensure continuous production and minimize downtime, maintaining cost efficiency.

Investing in advanced technology and regular equipment maintenance can lead to long-term savings in Vortioxetine Hydrobromide production, enhancing productivity and reducing operational risks.

5. Environmental and Regulatory Compliance

Pharmaceutical manufacturing is subject to strict environmental and regulatory standards to ensure product safety and minimize environmental impact. Compliance with these standards is critical but adds to production costs due to additional investments in emissions control, waste management, and monitoring.

Regulatory Compliance: Producing pharmaceuticals requires adherence to Good Manufacturing Practices (GMP) and environmental regulations, necessitating investments in clean technologies and regular inspections.

Environmental Impact Management: Companies must also manage their environmental footprint, including emissions, waste disposal, and water usage, to comply with regulatory standards. Sustainable practices can reduce the long-term cost burden while supporting corporate social responsibility.

Complying with environmental and regulatory requirements is essential for maintaining product integrity and reputation. Pharmaceutical companies benefit from incorporating sustainable practices and proactive regulatory management to control these compliance costs effectively.

How Procurement Resource’s Vortioxetine Hydrobromide Production Cost Reports Can Help

Procurement Resource offers detailed Vortioxetine Hydrobromide Production Cost Reports that provide insights into the complexities of production expenses. These reports are invaluable for stakeholders in the pharmaceutical industry, offering a full view of cost structure and helping to identify potential savings.

Here’s how our reports add value:

Detailed Cost Breakdown: Our reports provide a comprehensive breakdown of every cost factor in Vortioxetine Hydrobromide production, from raw materials and energy to labor and compliance. This allows businesses to gain visibility into their expenses and identify opportunities to cut costs.

Real-Time Data and Market Forecasts: With the pharmaceutical market constantly evolving, our reports offer up-to-date data and forecasts that support strategic decision-making based on the latest market trends.

Price Trends and Analysis: Understanding price trends in the pharmaceutical industry is critical for companies reliant on high-cost compounds like Vortioxetine Hydrobromide. Our reports track historical and current price movements, providing insights to help companies anticipate and manage cost fluctuations.

Benchmarking and Comparison: Compare your production costs with industry benchmarks to find areas where efficiency improvements or cost reductions are possible. Benchmarking is key to maintaining competitiveness in a dynamic market.

Procurement Strategies: We offer practical procurement strategies that help companies manage their supply chains more effectively, securing cost-efficient and reliable sources of raw materials and energy.

Benefits of Vortioxetine Hydrobromide Production Cost Reports for Your Business

Partnering with Procurement Resource offers pharmaceutical companies valuable insights that support better decision-making and cost optimization. Our Vortioxetine Hydrobromide Production Cost Reports simplify complex cost structures and provide actionable insights for procurement and resource management.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/vortioxetine-hydrobromide/ask-an-analyst

Optimized Cost Management: Our reports help businesses identify cost-saving opportunities, streamline production processes, and enhance profitability in the competitive pharmaceutical market.

Informed Procurement Decisions: Access to real-time pricing data allows companies to make well-informed procurement choices, reducing exposure to market volatility and securing a reliable supply of raw materials.

Regulatory and Environmental Compliance: Our reports provide insight into regulatory compliance costs and highlight sustainable production practices, helping companies align with industry standards and environmental goals.

Stay Ahead of Market Trends with Procurement Resource

At Procurement Resource, we understand that every business has unique needs. Our Vortioxetine Hydrobromide production cost reports are customizable, allowing companies to tailor the information to their specific requirements. Whether you’re a pharmaceutical manufacturer, a supplier, or an investor, our team of expert analysts is here to provide the insights needed to make informed decisions.

Request Your Free Sample Report Today

If you're ready to optimize your production process for Vortioxetine Hydrobromide and make strategic cost-saving decisions, request a free sample report from Procurement Resource. Our reports offer the knowledge and tools necessary to improve efficiency, manage costs, and stay competitive in the evolving pharmaceutical landscape.

Request Your Free Sample – https://www.procurementresource.com/production-cost-report-store/vortioxetine-hydrobromide/request-sample

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA & Canada: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA